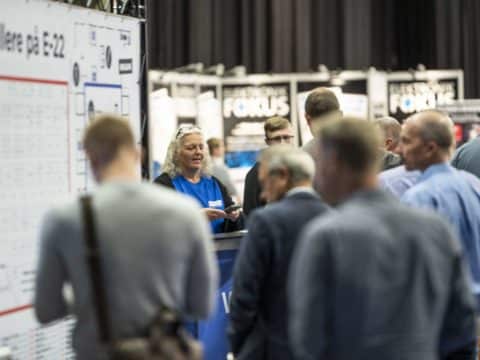

Velkommen til Danmarks største elektronikmesse

Ses vi den 3.-5. september 2024 i Odense Congress Center?

Vi sætter strøm til Elektronikmessen 2.0!

Til september 2024 åbner Odense Congress Center igen dørene til det største mødested for hele den danske elektronikbranche, og du har meget at se frem til. Som altid er Elektronikmessen stedet med hands-on produkter og maskiner, en masse nyheder, spændende konferencer og ikke mindst netværk.

Men i 2024 skruer vi ekstra op for ambitionerne og byder velkommen til Elektronikmessen version 2.0!

Her træder du for alvor ind i en verden af elektronik, når vores spritnye koncept med seks forskellige temaområder giver dig overblikket over hele elektronikrejsen fra design til leverance.

Oplev det nye koncept

Var du med til E-22? Så ved du allerede, at messen kunne fremvise de to temaområder: Udvikling i Danmark og Produktion i Danmark. Det tager vi skridtet videre i 2024. Her går vi all-in med hele seks temaområder, der sætter fokus på bibeholdelsen af elektronik i Danmark og taler ind i den grønne agenda, som har slået rod i det danske erhvervsliv. Temaerne Leverandører i Danmark og Startups i Danmark understøtter de øvrige fire, så hele elektronikrejsen vil være repræsenteret på Elektronikmessen.

- Design i Danmark – læs mere om temaområdet

- Udvikling i Danmark – læs mere om temaområdet

- Test i Danmark – læs mere om temaområdet

- Produktion i Danmark – læs mere om temaområdet

- Leverandører i Danmark – læs mere om temaområdet

- Startups i Danmark – læs mere om temaområdet

Gå ikke glip af årets højdepunkt i den danske elektronikbranche!

Elektronikmessen er stedet, du kan se, røre ved, høre om og stille spørgsmål til produkter, maskiner og elektronikløsninger. Det bliver ikke nemmere at være opdateret om alle tendenserne, få viden om komponenter eller udforske hvilke typer af producenter, udviklingshuse og leverandører, der står til rådighed, når det kommer til elektronik i Danmark.

Kontakt os

Vil du vide mere om dine muligheder for at blive udstiller? Eller har du spørgsmål om dit besøg på messen? Vi sidder klar til at hjælpe dig.

Kontakt os